Products

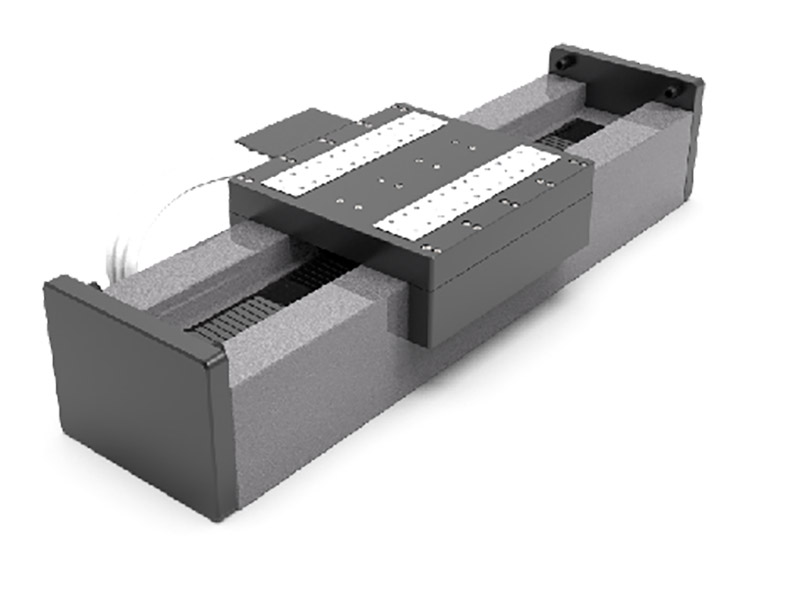

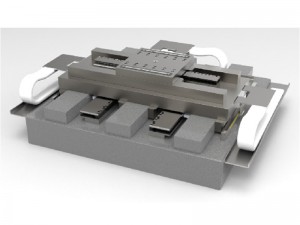

E-EC-ABL-X One-dimensional air floating motion stage

Design Feature Air-Bearing Design

the E-EC-ABL-X

features a smaller cross-section than typical air-bearing stages without sacrificing load capability. The large air-bearing surfaces provide excellent stiffness, allowing for heavy loading. Proprietary manufacturing techniques result in a stage with unsurpassed pitch, roll and yaw characteristics. Linear Motor Drive

The driving force behind this stage is Precision-stage brushless linear servomotor. The utilizes an ironless forcer, which means there is zero cogging and no attractive forces – resulting in unrivaled smoothness of motion. Since the stage is friction-free and the motor has zero cogging, extremely fine resolutions are achievable.

Zero Maintenance

The noncontact air bearing, noncontact linear motor drive and noncontact feedback device ensure years of maintenance-free operation at the high performance levels that are expected of equipment. Because there is no mechanical contact between moving elements, the E-EC-ABL-X experiences no wear or reduction in performance over time. Service life is virtually unlimited, and since there is no lubrication – only clean, dry gas – air bearings are ideal for clean room and medical applications.

Application Fields

positioning systems are ideally suited for many high-precision applications such as metrology, photonics, and precision scanning in semiconductor or flat panel display manufacturing.

Thanks to the friction-free motion, no particles are formed, which makes stages ideal for cleanroom applications.

Encoder

● filter and air preparation kits

● Single and multi-axis motion controller

● XY setups and individual configurations

● Base plates made of granite and systems for reducing vibration

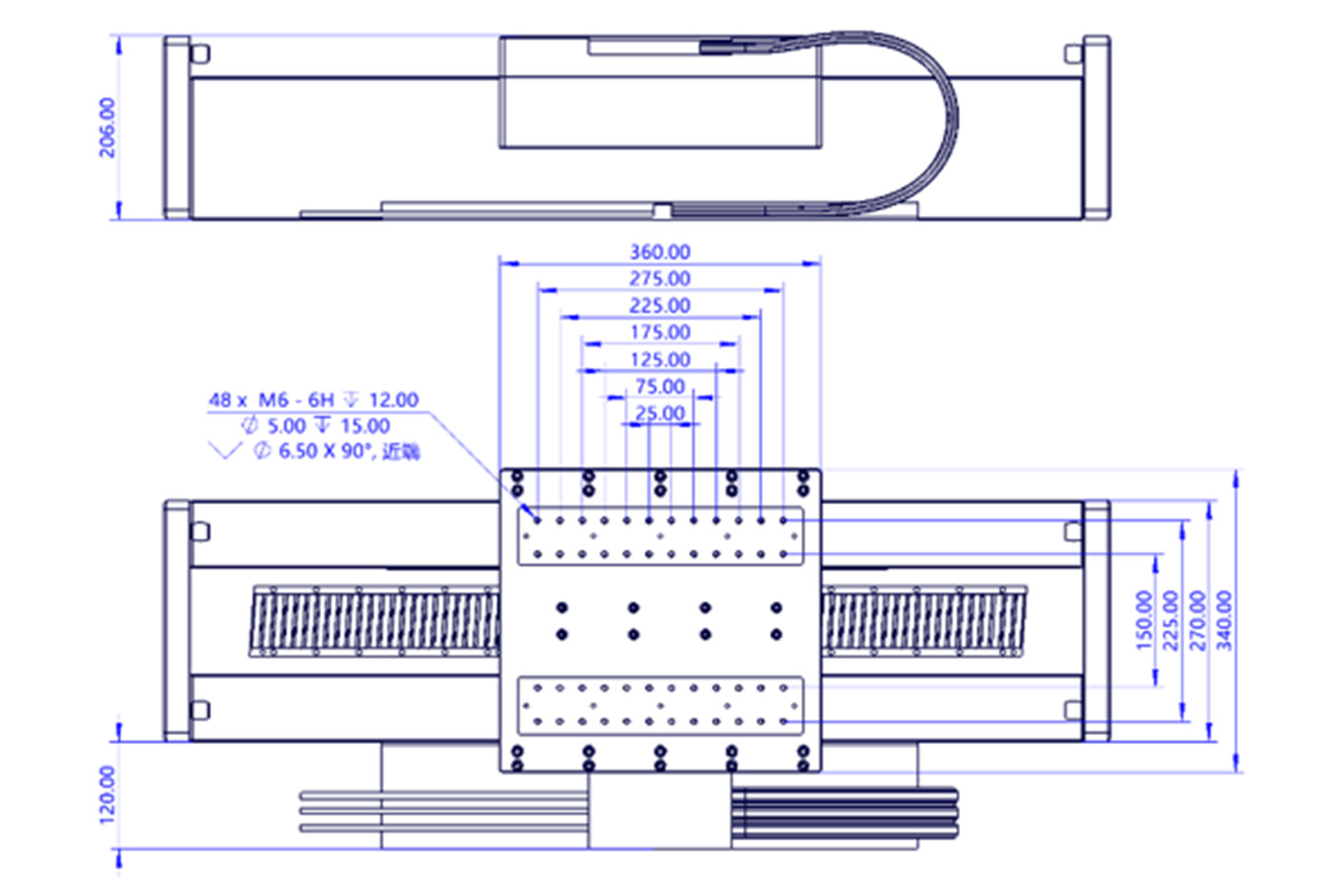

| Specification | ABLE340-500 | -1000 | ||

| Motor type | Linear motor with iron core | |||

| Opticval Encode resolution | Default 0.1um (optional analog, up to 1nm) | |||

| Motor thrust | Continuous 550N/peak 1100N | |||

| Acceleration(no load) | 5G | |||

| Travel [mm] | 500 | 1000 | ||

| Repeatability Accuracy [um] | ≤±0.3um (if optional 5nm grating, up to ±50nm) | |||

| Accuracy [um] | 2um/100mm (After calibration, it can be less than 0.5um/100mm) | |||

| Flatness [um] | ≤±0.5 | ≤±1 | ||

| Straightness [um] | ≤±0.5/20mm | |||

| Max Speed [mm/s] | 3000(depending on drive and stroke) | |||

| Max load capacity [kg] | 200kg | |||

1) What is “Nanopositioning”?

A: In the not-too-distant past, the precision tail-end of the bell curve in automation was often colloquially referred to as the “micropositioning” segment of the market. The term microposition derives from the fact that high-precision positioning systems were routinely operating at the micron level. Manufacturers in this space were specifying key system attributes such as Bi-directional repeatability, Accuracy, and Stability in units of microns. Such systems sufficiently filled industry demands from Life Science and Diagnostics, to Non-contact metrology, to the Tech sectors of Semiconductor, Data Storage, and Flat Panel Display.

Fast forward to our present day and no longer are such systems sufficient. Evolving industry needs in microscopy and biotechnology demand evolving levels of performance from precision positioning equipment manufacturers. As the features of interest across markets become smaller, the ability to position at the nanometer level becomes a market imperative.

2) Do you accept OEM?

A: Yes, OEM and ODM is warmly welcomed.

It is our company’s strength, we can customize the LCD monitor so that can fully meet customers’ requirements.

3) What payment methods does your company accept?

A: T/T, Western Union, Paypal and L/C.