Cov khoom

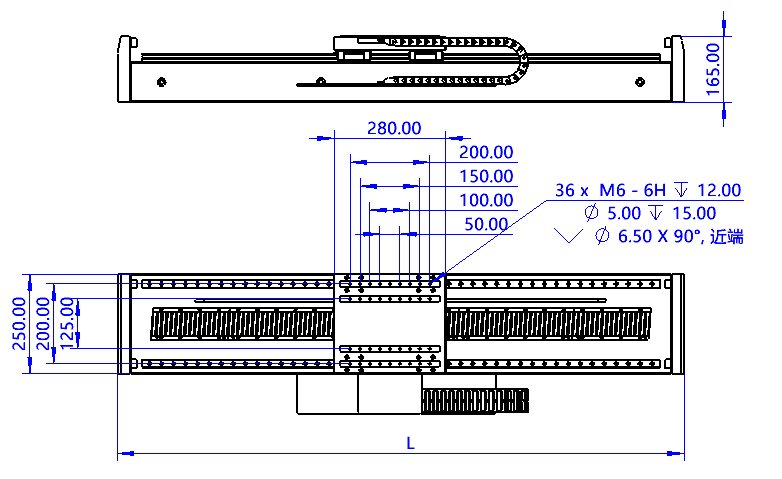

E-LMS250GT-X (linear positioning stage) Ib-dimensional linear motor motion stage

E-LMS250GT-X feature

●High-Speed Linear Stage • Siab Load Capacity • Linear Tsav • Marble puag • siab rigidity, • siab ncaj • siab precision;

●Ntev mus txawv tebchaws (500 mus rau 2000 hli) nrog nqaim profile (165 hli dav);

●Load peev xwm mus tas li rau 3000N;

●Highly dynamic, txij nkawm-dawb linear lub cev muaj zog nrog velocities mus txog 2 m / s;

●Robust industrial tsim rau lub neej ntev;

●High-precision incremental lossis absolute linear encoder;

●Marble puag, siab rigidity, siab ncaj, siab precision;

● Linear Motor Stage High-Speed Linear Stage;

● Muaj peev xwm thauj khoom siab • Tus nqi siv tau • Linear Tsav;

Kev Tsim Kho Kev Lag Luam

Kev tsim qauv tsim rau kev ua haujlwm siab thiab kev ua haujlwm siab

E-LMS250GT-XX yog lub luag haujlwm hnyav thiab muaj zog tshaj tawm theem rau kev lag luam.Nws cov qauv tsim tau zoo ib yam rau kev xav tau kev lag luam thiab nws yog tus cwj pwm los ntawm kev nruj nruj thiab kev siv cov khoom zoo: recirculating ball bearing guides, 3-theem linear motor, incremental or absolute linear encoder.Qhov kev daws teeb meem siab ntawm cov encoders tso cai rau kev taug qab kev ua tau zoo, kev taug qab me me yuam kev, thiab lub sijhawm luv luv.Kev lag luam-tshaj connectors muab kev sib txuas ceev thiab ruaj ntseg.

Linear motor nrog direct tsav

3-theem magnetic direct drives tsis siv cov khoom siv hauv lub tshuab tsav tsheb, lawv xa cov tsav tsheb mus rau lub platform txav ncaj qha thiab tsis muaj kev sib txhuam.

Cov tsav mus txog siab ceev thiab accelerations.Ironless motors yog tshwj xeeb tshaj yog haum rau qhov chaw ua hauj lwm nrog lub siab tshaj plaws xav tau ntawm precision vim hais tias tsis muaj undesirable cuam tshuam nrog cov hlau nplaum mus tas li.

Qhov no tso cai rau kev khiav haujlwm du txawm tias qhov qis tshaj plaws thiab tib lub sijhawm, tsis muaj kev vibration ntawm qhov siab tshaj.Nonlinearity hauv kev tswj tus cwj pwm raug zam thiab txhua txoj haujlwm tuaj yeem tswj tau yooj yim.Lub zog tsav tuaj yeem teeb tsa dawb.

Daim ntawv thov teb

Electronics manufacturing: PCB manufacturing, luam ntawv electronics.

Kev kuaj & tshuaj xyuas: Tsis sib cuag 2D ntsuas, ntsuas qhov ntsuas & lub koob yees duab tso rau kev tshuaj ntsuam, ntsuas qhov ntsuas qhov ntsuas, ntsuas kev vibration & acceleration.

Advanced manufacturing: Robotic manipulation thiab microassembly, muaj inkjet luam ntawv.

| Specification | LMS250GT-500X | -1000 X | - 1500 X | - 2000 X |

| Siv tau nrug [mm] | 500 | 1000 | 1500 | 2000 |

| Opticval Encode daws teeb meem [nm] | default 0.1um (Max 1nm yeem) | |||

| Repeatability Qhov tseeb [um] | ± 0.3 | |||

| Qhov tseeb [um] | 2um / 100mm (tsawg dua 0.5um / 100mm tom qab calibration) | |||

| Flatness [um] | ± 2.5 | ± 5 | ± 7.5 | ± 10 |

| Ncaj [um] | ± 2 | ± 5 | ± 7.5 | ± 10 |

| Max Ceev [m / s] | 2 | |||

| Max Acceleration [G] | 4 | |||

| Max load peev [kg] | 300 | |||

| L [mm] | 9 20 | 1420 | Xyoo 1920 | 24 20 |

1) "Nanopositioning" yog dab tsi?

A: Nyob rau yav dhau los tsis dhau deb, qhov tseeb qhov kawg ntawm lub tswb nkhaus hauv automation feem ntau hu ua "micropositioning" ntu ntawm kev ua lag luam.Lub sij hawm microposition muab los ntawm qhov tseeb hais tias high-precision positioning systems tau niaj hnub ua haujlwm ntawm qib micron.Cov neeg tsim khoom nyob rau hauv qhov chaw no tau qhia txog cov yam ntxwv tseem ceeb xws li Bi-directional repeatability, Accuracy, thiab Stability nyob rau hauv units ntawm microns.Cov tshuab no tau ua tiav kev lag luam txaus los ntawm Kev Tshawb Fawb Txog Lub Neej thiab Kev Tshawb Fawb, mus rau Non-contact metrology, mus rau Tech sectors ntawm Semiconductor, Data Storage, thiab Flat Panel Display.

Ceev ceev rau pem hauv ntej rau peb niaj hnub tam sim no thiab tsis muaj cov tshuab zoo li no txaus.Evolving kev lag luam xav tau nyob rau hauv microscopy thiab biotechnology thov evolving theem ntawm kev ua tau zoo los ntawm precision positioning khoom manufacturers.Raws li cov yam ntxwv ntawm kev txaus siab thoob plaws kev lag luam dhau los ua me, lub peev xwm los ua haujlwm ntawm qib nanometer dhau los ua kev lag luam tseem ceeb.

2) Puas yog koj cov khoom xa tuaj txawv teb chaws?

A: Yog, peb xa peb cov khoom thoob ntiaj teb thiab muaj cov neeg xa khoom hauv cheeb tsam.

3) Yuav ua li cas kuv thiaj li thov tau ib nqe lus ntawm ib yam khoom?

A: Koj tuaj yeem xa email rau peb, peb yuav ua cov lus hais rau koj.

4) Cov khoom puas yog customizable?

A: We muab cov kev daws teeb meem zoo tshaj plaws rau peb cov neeg siv khoom.Feem ntau qhov no suav nrog kev kho lossis teeb tsa peb cov khoom lag luam rau tus neeg siv khoom tshwj xeeb thiab cov lus qhia tshwj xeeb.Thov hu rau peb yog tias koj txaus siab rau customizing los yog configuring ib qho ntawm peb cov khoom txheem, los yog yog hais tias koj xav mus ua hauj lwm nrog peb engineering pab neeg los tsim ib tug tshwj xeeb kev daws teeb meem kom tau raws li koj cov kev xav tau ntawm cov lus tawm tswv yim.Yog tias qhov kev tshaj tawm no dhau mus, qhov kev sib hloov pib pib tsis siv tau lawm, thiab kev sib hloov yuav tsum tau rov ua dua.

5) Dab tsi yog gantry theem?

A: Cov theem gantry yog tsim los muab cov kev ua tsis tau zoo dua qub thiab muaj txiaj ntsig zoo hauv kev ua haujlwm hauv ntiaj teb tiag.Peb cov theem gantry yog tsim los txav cov khoom xws li tshuaj xyuas lub koob yees duab, laser taub hau, lossis cov neeg siv khoom tshwj xeeb tshaj li tshem tau cov substrates lossis fixtures mounted rau hauv paus ntawm lub system.Lub hauv paus gantry tuaj yeem muab nrog lub qhov txuas rau kev cuam tshuam tus neeg siv khoom kho vajtse mus rau theem.Vim nws txoj kev yooj yim thiab yooj yim ntawm kev sib dhos, nws yog qhov zoo tshaj plaws gantry theem teeb tsa rau OEMS thiab cov txheej txheem kev sib koom ua ke tsim cov cav tov rau kev thov.Ntau yam ntawm Dover Motion tus qauv ntsia hlau tsav thiab servo motor linear khoom tuaj yeem ua ke ua ke raws li theem gantry kom ua tiav daim ntawv thov qhov tseeb thiab kev mus ncig rau XYZ tsab ntawv tsa suab.

●Pre-formatted puag kom yooj yim ntawm kev koom ua ke;

● Risers los muab qhov chaw nruab nrab ntawm lub hauv paus thiab txav nqaj;

●Integrated cable lem thiab hi flex cable;

●Tag nrho cov axes sim ua ke thiab hlawv kom ntseeg tau tias kev ua tau zoo thiab kev ntseeg siab tau ua tiav ua ntej xa khoom xa tuaj.